Xtool vs Thunder Laser - Xtool Reviews

Thunder is 4x faster than Competitor X

All of our machines engrave at speeds up to 1,000 mm/s which is almost twice as fast as the Competitor X 600 mm/s. Additionally, our motors actually accelerate faster (3G) as well, which is how we will produce engravings up to four times as fast.

Read the In-Depth Review Here

Setup…

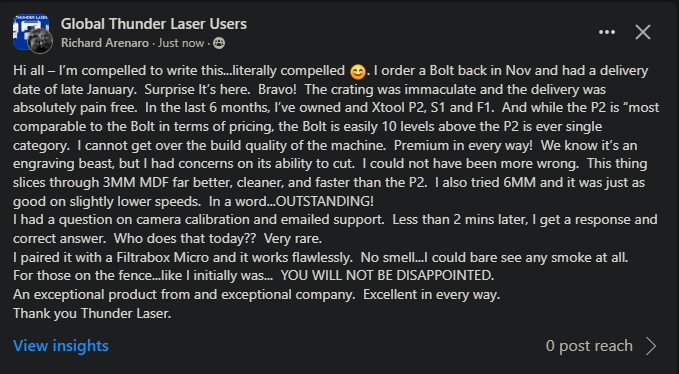

Again, the P2 is a good machine. It’s reasonably well built, but certainly the parts are not up to the quality of those used in the Bolt. I’ve owned and worked with both, and there is simply no comparison. Again, I’m a hobbyist, I’m not running a laser-based business. But I can imagine that the smart choices made by Thunder will serve that population equally as well. Every area of the Bolt that might need servicing has its own access panels and is easily accessible. I have not had to service the Bolt, but each component is clean, free of clutter and identifiable. I’ve seen videos on replacing components on the P2 and it’s not for the faint of heart. Quite frankly, I don’t see how this sustainable over the long run. By comparison, the P2, individual parts are not very accessible and the 12 or so screws inside and outside of the laser just to access the laser tube if very frustrating. Not to mention the not-so-easy to snap off plastic cover that houses the laser tube. To me, these are design failures. In practicality, the Bolt, which uses an RF based laser, and which is low maintenance, is designed to be easily accessible. Whereas the P2, which uses tube based C02 laser, (requires anti-freeze, etc) and which, in general, is likely to be accessed considerably more, is covered is plastic and secured by many poorly placed screws. I had to access the laser area of the P2 more than 5 times, and it was very frustrating. Sure, I can leave off half the screws, but why should I have to? I was told by Xtool, that it was designed that way for safety. I could not disagree more. More screws don’t equate better safety. The Bolt is all metal, has a secure key based entry system and the laser cover simply flips open. In my opinion, poor accessibility increases the likelihood that you’ll ignore standard maintenance and cleaning, thereby decreasing safety. I could cover a few more of the design decisions, but they fall under the same themes. Intentional design from a user and serviceability standpoint is critical. The Bolt hits all those points. Just a quick mention here. I don’t want to get into a feature list comparison because those things already exist. But…probe based focusing AND a camera are great choices. I realize that others may never use the camera. But I resent a company telling me I don’t “need” a camera (take note to the Xtool S1). Let me decide based on my experience and use case. (Excellent choices Thunder.

Performance…

Cutting – this is the area that I researched most and surprisingly had the least amount of available information… pre-purchase. Most reviews focused on the Bolt’s engraving prowess….and rightfully so. It is a beast in that area. The opinions I saw on cutting were very positive, but more secondary in nature. So, prior to delivery, it remained a concern. So how does it cut? One word…fantastic! It slices through 3MM MDF and ply far better, cleaner, and faster than the P2. I also tried 6MM and it was just as good on slightly lower speeds of course. I was doing some engraving tests with standard food cutting boards and decided to slice and dice them before disposal. End results were exceptionally clean cuts and some carving boards that looked like jigsaw puzzles. Also, acrylic cut flawless with little regard to thickness. Again, I’m not a fan of testing the extremes and I’m not looking to use this is place of a table saw. But I’ve personally, and in real world use and testing, experience zero issue with cutting material. In both my standard use of the machine and in my workflows, I can see no issues with cutting. In comparison, the results are far better than the P2. The airflow and back flash on the Bolt are way less and cuts are just cleaner.

Other topics…

Areas for improvement – none on the machine. I’m sure I can ask for more things over time. Who doesn’t want more? I’d love to see more video reviews on cutting and an increased social media presence. Not to the Xtool level or Glowforge…which is oversaturated in my opinion. This will help answer (for example) one of the most asked question…how does it cut? Website…maybe a little more user friendly and less industrial. Thunder, your support is outstanding, don’t burry the knowledge center. Same for the accessories area. Make it clearly visible and have the easy ability to purchase parts. I do know it exists, but maybe organize it to a more consumer focused look and feel. Make it a little more inviting.

Closing…

Why People Choose Us Over Others

Works Flawlessly

With LightBurn

While “Competitor X” is semi-compatible with LightBurn, many users find the functionality to be limited at best. Make sure you get a machine that fully runs on LightBurn!

High-Quality Parts Means Better Engraving

Our machines are incredibly well made with materials we often machine. Lots of machines out there can be made of cheap plastic that shake when engraving, producing poor results.

Wicked-fast,

US-Based Support

When you neaed help, you need it fast. Like lightning fast. We typically respond in 3-5 minutes, often on weekends and holidays.

How Are Thunder Laser Machines Different From Others

01

No Painful Alignments

All of our machines will arrive to you perfectly aligned. No painful adjusting required. Be up and running in no time! Poorly made machines often require periodic alignments, costing you precious laser time.

Read More

If you have to spend an hour or two aligning your machine every couple of weeks, what does that do to your productivity? Machine reliability is crucial if you are running a small business. Our machines only come out of alignment in the event of a head crash.

02

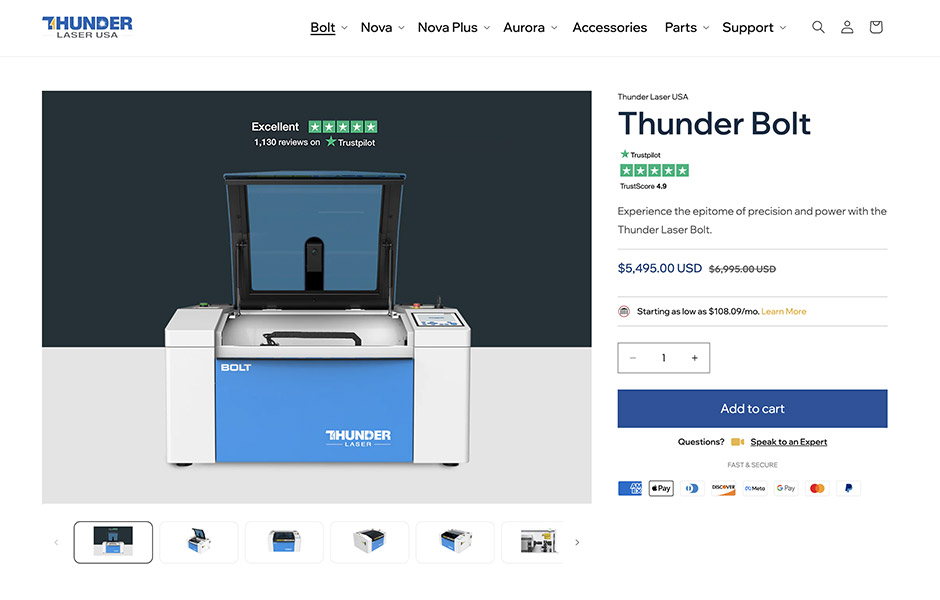

We Have Clear, Consistent Pricing

Our pricing is clear and upfront and includes everything you need to run a standard job. So you never have to worry if you are getting the best deal.

03

Don’t take our word for it, join Facebook groups and ask other users.

It’s hard to really know the differences in lasers without seeing them up close in action. We would encourage you to join different Facebook groups and ask the community about their machines. Visit our page.

Competitor X vs Thunder Comparison: Xtool Review

We don’t really like specs sheets, because they can be deceiving. It’s not always apples to apples. The overall build quality of the machine will be the best determining factor in how well a laser operates. But we do understand sometimes you need to compare different brands.

So we built this for you:

| Competitor X | Thunder Bolt | Nova 24 | Nova 35 | Notes | |

|---|---|---|---|---|---|

| Base Price | $4,999 | $5,495 | $7,400 | $9,900 | |

| Working Area | 26” x 14” | 20” x 12” | 24” x 16” | 35” x 24” | |

| Speed | 600mm/s | 1000mm/s | 1000mm/s | 1000mm/s | Thunder is 3-4x faster than Glowforge |

| Build Quality | Hobbyist Grade | Industrial Grade | Industrial Grade | Industrial Grade | |

| Tube | 55W Glass | 30W RF | 60W Glass | 80W Glass | 30W RF has cutting capacity of 45W Glass |

| Heat Alarm | Optional | Yes | Yes | Yes | Safety Feature for Fire Hazard |

| Red Dot | No | Yes | Yes | Yes | For locating the laser beam |

| Chilling Needs | Water Pump Included | Air Cooled RF TUBE | Water Chiller CW5000 | Water Chiller CW5000 | Glass tubes need chilled water to extend life |

| Camera | Built-In | Built-In | Optional | Optional | |

| Internal Memory | Unknown | 1000MB | 1000MB | 1000MB | |

| Z-axis Movement | 3” | 4.3” | 6.1” | 9” | |

| Warranty | One Year | Two Years | Two Years | Two Years |

Choose From Our Cutting Edge Options Of Laser Machines

Thunder Laser USA

Your Business Deserves Better Than “Good Enough”.

It’s time to invest in a machine that works as hard as you do.