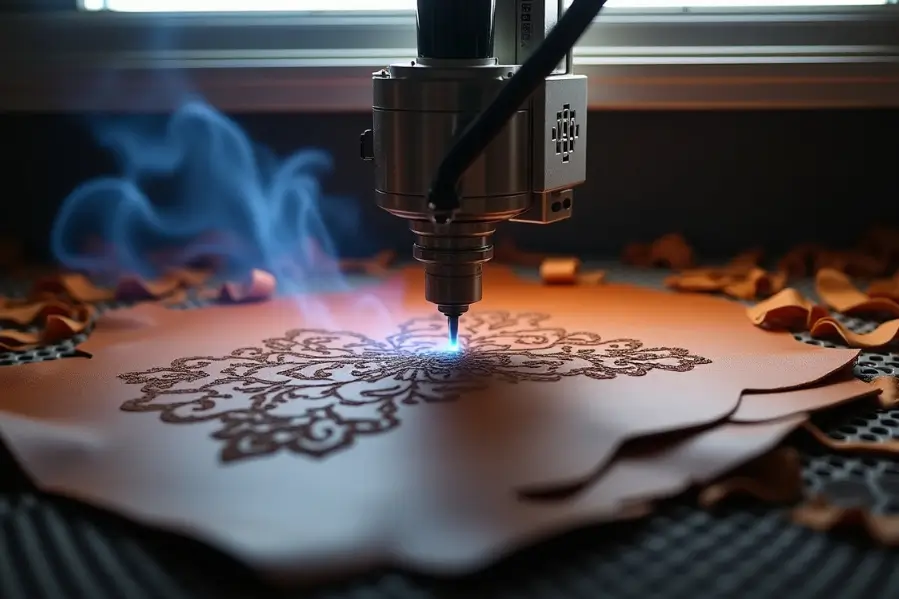

Laser cutting leather is a precise way to create clean edges and detailed designs. It allows crafters to cut patterns that are hard to achieve by hand.

This method uses a focused laser beam to slice through leather smoothly, reducing the need for extra trimming or finishing. The result is a sharp, professional look with minimal waste.

Whether you’re making bags, wallets, or custom pieces, laser cutting helps turn ideas into polished leather products with accuracy and ease.

What to Know About Leather for Laser Cutting

Learn how different types of leather react to laser cutting and what to consider when choosing the best material for your projects.

1. Types of Leather

Leather can be classified into several categories, each offering unique characteristics. The most common types for laser cutting include:

- Full-Grain Leather: This is the highest quality leather, made from the outer layer of the hide. It retains its natural grain, which gives it durability and a premium look.

- Split Leather: Produced by splitting the hide, this type has a less pronounced grain and is often used for less expensive products. It’s more porous and may require different settings for laser cutting.

- Suede: Made from the inner layer of the hide, suede has a soft texture and a napped finish. It can be challenging to cut cleanly, as the fibers can fray when exposed to a laser.

Understanding these types allows for better anticipation of how each will react during the cutting process.

2. Choosing the Right Leather for Laser Cutting

Selecting the correct leather for a project involves considering both the desired outcome and the properties of the material.

- Thickness: Thicker leathers may require more power and slower cutting speeds to achieve clean edges.

- Finish: Smooth finishes tend to cut more cleanly than textured ones.

- Moisture Content: Proper conditioning is vital. Leather should be dry and treated to avoid complications during laser cutting.

These factors greatly influence the techniques used and the quality of the final piece. A well-prepared leather will lead to more precise cuts and enhanced design potential.

Techniques and Best Practices for Laser Cutting

Discover essential techniques and best practices to achieve clean, accurate, and consistent results when laser cutting leather.

1. Preparing Your Leather

Before starting the laser cutting process, it’s essential to prepare the leather properly. First, inspect the leather for any imperfections, such as scratches or uneven surfaces, as these can affect the cutting outcome.

Next, clean the leather to remove dust and debris. A clean surface ensures that the laser interacts properly with the material, reducing the potential for errors.

Additionally, it’s important to choose the right type of leather based on the project. Different leather types, such as vegetable-tanned or chrome-tanned, might respond differently to laser cutting. Determine the thickness, as this will influence the laser cutter settings.

2. Laser Cutter Settings and Configuration

Setting up your laser cutter correctly is key to getting clean, accurate cuts. The main settings to adjust are power, speed, and frequency.

Use higher power for thicker leather to ensure full cuts. Lower speed gives the laser more time to cut cleanly through the material. Adjust frequency to control how often the laser pulses, which affects the smoothness of the edges.

Always use vector designs for precise path cutting. Before starting your main project, run test cuts on scrap leather to fine-tune your settings.

3. Step-By-Step Laser Cutting Procedure

The laser cutting procedure involves a few critical steps to ensure accuracy.

- Design Preparation: Create or import a vector design into the laser cutting software. This design should be optimized for cutting, with clear lines and no overlapping paths.

- Setup the Machine: Load the laser cutter with the prepared leather, ensuring it is flat and secured to prevent movement.

- Adjust Settings: Input the predetermined settings for power, speed, and frequency based on the type and thickness of the leather.

- Perform a Test Cut: Conduct a test cut on a similar scrap piece to verify accuracy and quality.

- Execute the Final Cut: Once satisfied with the test, run the laser cutter with the final design on the prepared leather.

- Post-Cut Finishing: After cutting, inspect the edges and clean any remnants to achieve a polished look.

Properly following these steps leads to high-quality outcomes in leather cutting projects.

Popular Uses for Laser-Cut Leather

Explore the most common and creative ways laser-cut leather is used in products like accessories, home décor, fashion, and personalized gifts.

1. Fashion and Accessories

In the realm of fashion, laser-cut leather is prominently featured in items such as purses, wallets, and shoes. The technology enables designers to create detailed patterns and shapes that enhance the aesthetic appeal of accessories.

Bracelets and necklaces also benefit from laser cutting, with personalized engravings and unique styles. The edges of laser-cut items remain sealed, preventing fraying, which preserves the quality of these leather pieces. This durability is particularly important for everyday wear items.

2. Home Decor and Functional Items

Laser-cut leather is gaining traction in home decor, with applications in items like coasters and bookmarks. These products can be customized with intricate designs, making them both functional and visually appealing.

Briefcases and keychains represent another segment where laser cutting shines. They offer users personalized touches while maintaining robustness. The exactness of laser cutting ensures that even the most complex designs can be realized, maximizing the aesthetic and practical use of leather in everyday items.

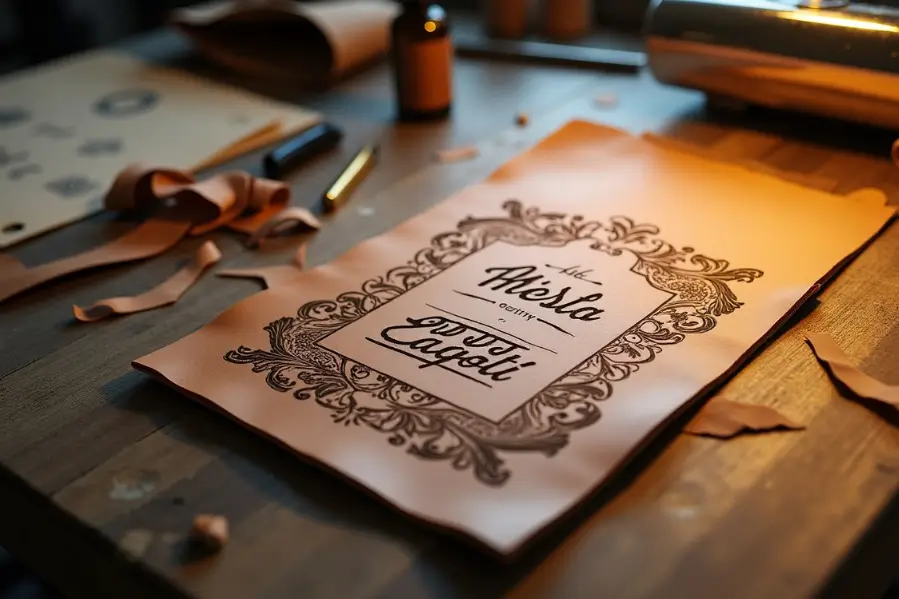

Customization and Personalization

The ability to customize and personalize leather products has gained significant traction in recent years. Techniques such as laser engraving allow for intricate patterns and detailed designs, making each piece unique.

1. Laser Engraving for Detailed Designs

Laser engraving is a precise method used to create intricate designs on leather surfaces. This technology utilizes a focused laser beam to etch patterns directly onto the material.

It offers an impressive level of detail that traditional methods cannot match.

Key benefits of laser engraving include:

- Customization: Individuals can add names, initials, or specific designs that reflect personal style.

- Versatility: It can be applied to various leather types, from wallets to bags.

With laser engraving, designers can explore unlimited creative possibilities while ensuring consistent quality.

2. Creating Unique Personalized Products

The process of creating personalized leather goods extends beyond simple designs. It encompasses the fusion of artistry and technology to produce items tailored to individual preferences.

For instance, custom leather products like belts and journals can feature engraved logos or designs.

This personalization enhances the value and appeal of the item. Customers often seek these unique touches for gifts or personal use.

In summary, engraving leather not only beautifies the product but also infuses it with a personal story, resulting in pieces that resonate on a deeper level.

Final Thoughts

Laser cutting leather is a powerful way to create detailed, professional-quality products with precision and consistency. From fashion accessories to home décor and personalized gifts, the possibilities are endless.

With the right technique, proper materials, and a reliable machine, you can take your leather projects to the next level—whether you’re crafting for fun or building a business.

Explore our top-rated laser cutters for leather and find the perfect machine to bring your ideas to life.

Frequently Asked Questions

1. What settings should I use for laser cutting leather?

For cutting leather, optimal settings depend on the type and thickness of the material. Typically, users should start with a power setting around 20-30% and a speed of 10-20 mm/s for materials up to 1/8 inch thick. Adjustments may be necessary based on the specific laser cutter and leather type.

2. What are the best laser cutters on the market for cutting leather?

Some top laser cutters for leather include the Epilog Zing, Glowforge, and Thunder Laser machines. These models are known for their precision and ease of use. Features such as adjustable wattage and cutting speed contribute to their effectiveness in leather applications.

3. What options are available for leather laser cutting services?

Numerous services offer leather laser cutting for various projects. Local makerspaces and fabrication shops often provide these services, as do specialized online companies. Customization options can range from simple cuts to intricate designs based on customer specifications.