Cutting vinyl with a laser cutter is a precise and efficient method for creating custom designs. It allows you to produce clean cuts and detailed shapes for signs, stickers, and decals. However, vinyl requires careful handling because it can release harmful gases when cut incorrectly.

This guide explains how to safely and effectively cut vinyl using a laser cutter. You will learn about the right materials, machine settings, and safety precautions to follow.

By the end, you will understand the best practices for cutting vinyl cleanly and safely. This ensures high-quality results without damaging your equipment or risking your health.

Understanding Vinyl Cutting with Laser Technology

Laser cutting is an accurate and efficient way to cut vinyl, allowing for detailed and complex designs. In this section, we will cover the basics of how laser cutting works, the types of vinyl that can be cut, and the different laser cutters used for vinyl projects.

1. Fundamentals of Laser Cutting

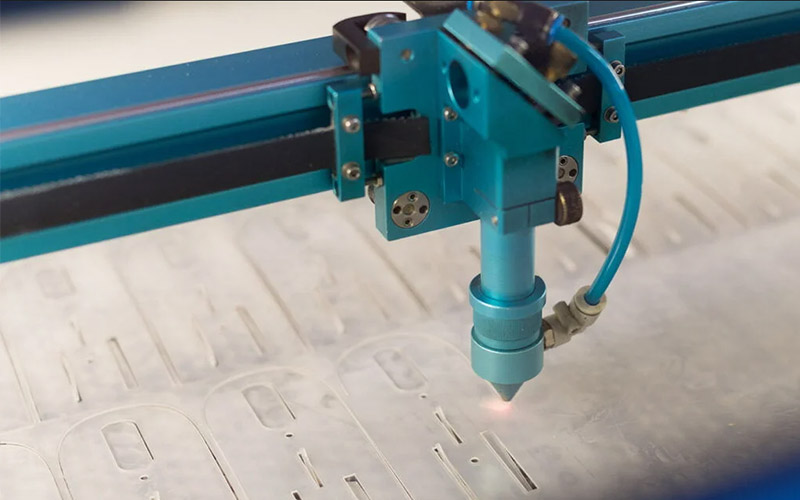

Laser cutting uses a focused laser beam to cut or engrave materials. When cutting vinyl, the laser melts, burns, or vaporizes the material to create clean and precise cuts. This method makes it possible to produce intricate shapes that are difficult to achieve with traditional tools.

The process is controlled by a computer, which directs the laser with high accuracy. As the laser cuts, it seals the edges of the vinyl, preventing fraying and giving the finished piece a smooth, polished look.

2. Types of Vinyl for Laser Cutting

Choosing the right vinyl is important for safe and effective laser cutting. Common types include PVC and PVC-free vinyl materials. PVC vinyl is strong and versatile, often used for signs, decals, and craft projects.

However, cutting PVC releases harmful chlorine gas, which can damage the laser cutter and harm the operator’s health. If you work with PVC, it is critical to have proper ventilation and follow safety guidelines. Many users prefer PVC-free options, such as polyurethane vinyl, which are safer and easier to cut without hazardous fumes.

3. Laser Cutter Types and Their Uses

There are different types of laser cutters suited for vinyl cutting. CO2 laser cutters are the most popular choice. They are effective for cutting soft materials like vinyl and can handle a variety of thicknesses.

CO2 lasers use a gas mixture to create a high-powered beam that cuts cleanly and efficiently. Fiber lasers, while excellent for metals, are generally not used for vinyl cutting. When selecting a laser cutter, it’s important to consider factors like power, cutting speed, and cost. Regular maintenance—such as cleaning the lens and checking the ventilation system—also helps keep the machine running smoothly and extends its lifespan.

How to Prepare and Work Safely with Laser Cutters for Vinyl

Before operating a laser cutter for vinyl, it is crucial to prioritize preparation and safety. Proper ventilation and material handling will significantly reduce health risks and equipment damage.

1. Ensuring Proper Ventilation

Cutting vinyl can release toxic fumes that are harmful to your health. A good ventilation system is necessary to keep the air clean and safe.

- Use an Exhaust System: Set up an exhaust system to remove harmful gases from your workspace.

- Open Windows and Doors: Increase airflow by opening windows and doors if possible.

- Wear Protective Gear: Wear a mask or respirator designed to filter out toxic fumes.

Proper ventilation protects both the operator and the machine. It also helps prevent residue buildup inside the laser cutter.

2. Material Preparation and Handling

Preparing your vinyl correctly before cutting is just as important as using the right equipment.

- Inspect the Vinyl: Make sure the vinyl is clean and free of dust or debris. Contaminants can affect the quality of the cut.

- Choose the Right Thickness: Use vinyl with an appropriate thickness. Thicker materials may need different laser settings, while thin vinyl can cut too quickly and lead to errors.

- Avoid Mixing Materials: Only cut one type of material at a time. Do not mix vinyl with metals, as this can damage the laser cutter and create harmful fumes.

Careful handling and preparation improve cutting results and keep your equipment safe.

How to Cut Vinyl Using a Laser Cutter for Clean Results

Cutting vinyl with a laser cutter requires careful setup and attention to detail. Following the correct steps ensures clean cuts, precise designs, and high-quality results.

1. Setting Up the Laser Cutter

Start by placing the vinyl flat on the laser cutter bed. Make sure there are no wrinkles or bubbles. This helps achieve an even and accurate cut.

Adjust the laser settings based on the type and thickness of the vinyl. Standard vinyl usually needs lower power, while thicker vinyl may need more power. Always check your machine’s user manual for recommended settings.

Using a low-tack adhesive mat can keep the vinyl in place during cutting. This prevents shifting and ensures clean cuts. Also, make sure the cutting bed is clean. Dust or debris can affect the cutting accuracy.

2. Weeding and Post-Processing

After cutting, remove the extra vinyl from around the design. This process is called weeding. Use a weeding tool to carefully peel away the unwanted parts.

Let the vinyl cool before you start weeding. This helps avoid stretching or distorting the design. Pay close attention to small details when removing excess vinyl.

Once weeding is done, the vinyl is ready to use. If you’re applying heat transfer vinyl, preheat your surface and follow the temperature guidelines for your vinyl type. This ensures good adhesion and a clean finish.

3. Troubleshooting Common Cutting Issues

Sometimes problems happen during cutting. Knowing how to fix them can save time and materials.

- Incomplete Cuts: If the vinyl isn’t cutting all the way through, try increasing the laser power or lowering the speed.

- Burn Marks or Scorching: Reduce the power or increase the speed to prevent overheating the vinyl.

- Misalignment: Check that the vinyl is straight on the bed. You should also calibrate the laser cutter regularly to avoid alignment issues.

By following these steps and making adjustments when needed, you can get clean and accurate cuts for your vinyl projects.

Applications and Project Ideas

Laser cutting vinyl is useful for many creative and commercial projects. It allows for precise, detailed designs that can be used in art, decoration, and business products. Below are common applications and project ideas for laser-cut vinyl.

1. Creative Vinyl Projects

Creative projects using laser-cut vinyl can be diverse and innovative. From wall decor to customized signage, the possibilities are extensive.

- Wall Art: Vinyl records or sheets can be laser cut into detailed wall decorations. These make unique art pieces for homes or offices.

- Personalized Decals: Adhesive vinyl can be cut into custom decals. These are popular for decorating walls, laptops, cars, and personal items with names, logos, or custom designs.

- Event Decorations: Heat transfer vinyl (HTV) can be used to make banners, table decor, and fabric backdrops for events. This helps create a coordinated and professional look for parties, weddings, and corporate events.

2. Commercial Applications of Laser-Cut Vinyl

Businesses use laser-cut vinyl for branding, marketing, and interior design. It offers affordable, high-quality solutions for different industries.

- Retail Signage: Stores use laser-cut vinyl for window signs, wall graphics, and product labels. It helps attract customers and build brand identity.

- Promotional Items: Companies create custom stickers, product labels, and packaging with laser-cut vinyl. These items are useful for giveaways and brand promotions.

- Interior Design: Designers use vinyl for decorating furniture, walls, and fixtures. Laser cutting allows for precise patterns that can be applied to surfaces like wood, glass, and acrylic.

Ready to Get Started with Laser Cutting Vinyl?

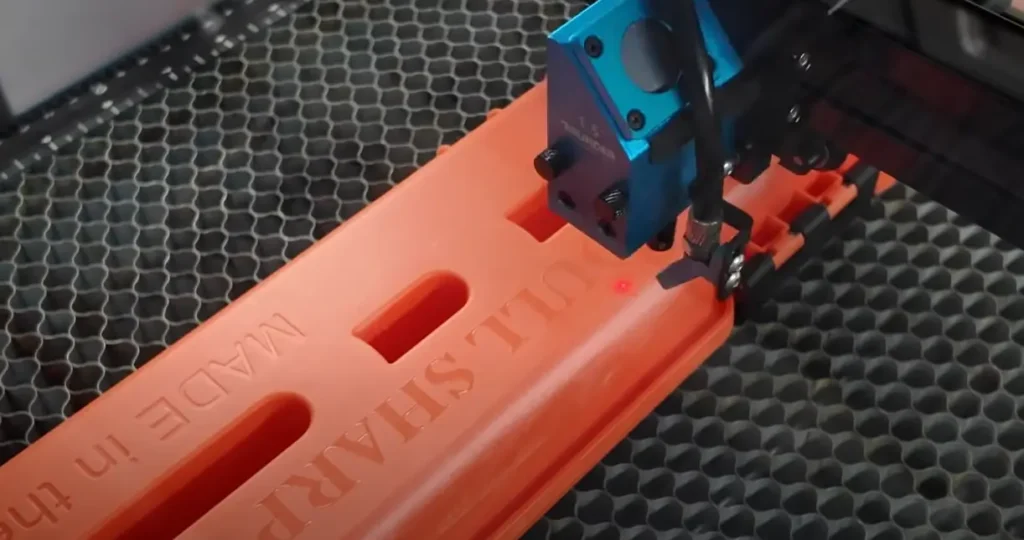

Thunder Laser USA offers high-quality laser cutting machines that make working with vinyl safer and easier. Our CO2 laser cutters deliver precision and reliability, perfect for cutting PVC-free vinyl and heat transfer vinyl (HTV).

Explore Thunder Laser USA Machines and take your vinyl cutting projects to the next level!

Frequently Asked Questions

Cutting vinyl with a laser cutter raises various questions about safety, suitability of materials, and techniques. Understanding these aspects can lead to successful and safe outcomes in projects involving vinyl.

1. Is it safe to cut vinyl using a laser cutter?

Cutting vinyl with a laser cutter is not generally safe. The process can release toxic fumes that are harmful to health. Adequate ventilation and proper safety measures are essential to minimize risks.

2. What type of vinyl is suitable for laser cutting without releasing harmful fumes?

Certain types of vinyl are safer than others for laser cutting. PVC vinyl, commonly used for various applications, produces harmful gases when cut. Opting for alternatives like heat transfer vinyl can reduce health risks, but checking the manufacturer’s guidelines is recommended.

3. Can you laser cut PVC free vinyl?

Yes, you can laser cut PVC-free vinyl. These materials do not contain chlorine, making them safer for laser cutting. Choosing laser-safe vinyl is important to reduce health risks and protect your equipment during the cutting process.

4. Can I laser cut heat transfer vinyl?

Yes, you can laser cut heat transfer vinyl (HTV), including Siser® HTV. Using a laser cutter is a fast and accurate method to achieve clean, detailed cuts—especially if you don’t have access to a traditional vinyl cutter.