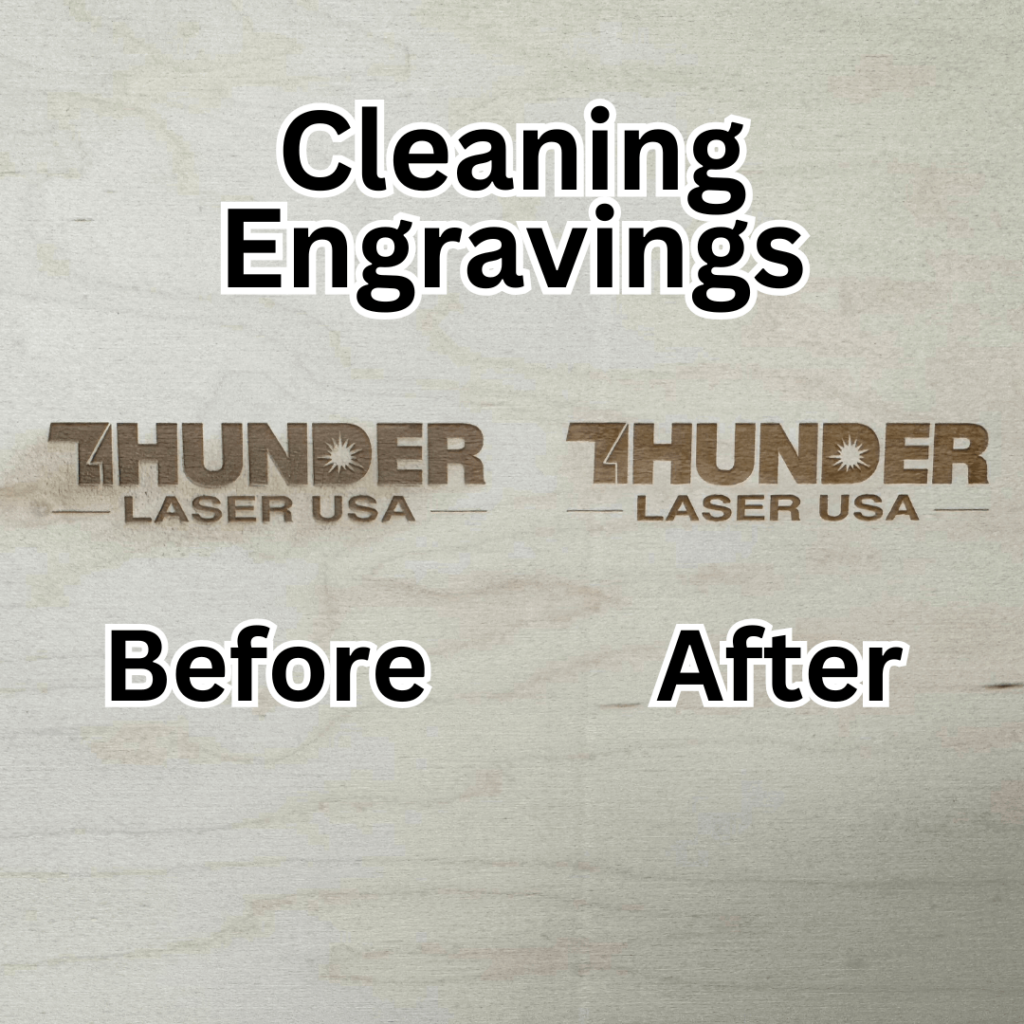

Laser engraving on wood creates detailed and precise designs. However, it often leaves behind residue, smoke stains, and debris that can affect the final look. Cleaning the wood properly is an important step to achieve a smooth and polished finish.

This guide explains simple methods to clean wood after laser engraving. You will learn what tools and materials to use, and how to remove residue without damaging the surface.

Follow these steps to protect your design and improve the overall appearance of your engraved wood projects.

The Fundamentals of the Engraving Process

Understanding the engraving process helps you prepare the wood and reduces the amount of cleaning needed after laser engraving.

1. The Basics of Laser Engraving

Laser engraving uses a high-powered laser beam to burn or etch designs into the surface of wood. The heat from the laser removes layers of material, creating permanent marks or patterns. Different settings control the depth and darkness of the engraving.

This process often produces smoke and fine dust, which can settle on the wood. Knowing how the laser works helps you understand why cleaning is necessary after engraving.

2. Pre-Engraving Preparation

Proper preparation of the wood before engraving reduces the need for heavy cleaning later. Start by sanding the surface to make it smooth and free of dirt or oils. Clean the wood with a dry cloth to remove any dust.

You can also apply masking tape to protect areas from smoke stains. Good preparation helps produce cleaner engravings and makes the final cleaning easier.

Best Cleaning Methods for Engraved Wood (Top 2 Ways)

Cleaning laser engraved wood requires specific techniques to preserve the quality of both the engraving and the wood itself. The following methods focus on effectively removing residue while protecting the integrity of the material.

1. Dry Cleaning Techniques

For initial cleanup, dry cleaning methods can be very effective. Using a soft brush can help dislodge and remove debris from the engraved areas without causing scratches. A microfiber cloth is another excellent option; it gently captures dust and particles without leaving lint behind.

To use these tools effectively, one can follow these steps:

- Brush gently over the surface to lift away dust.

- Wipe with a microfiber cloth in a circular motion to avoid pushing dirt deeper into the grain.

These techniques are particularly useful for delicate engravings, ensuring that the details remain intact while achieving a clean surface.

2. Applying Mild Cleaning Solutions

When dry cleaning isn’t sufficient, applying a mild cleaning solution may be necessary. A natural hand cleaner or orange hand cleaner can effectively remove stubborn residue. These cleaners are typically less abrasive and safe for use on wood.

Steps for this method include:

- Lightly dampen a microfiber cloth with the cleaning solution, making sure it’s moist but not soaking wet.

- Carefully wipe the engraved areas, focusing on any marks or residue.

- Rinse the cloth and wipe again to remove any cleaning solution residues.

This approach helps maintain the beauty of the engraving while ensuring the wood is free from contaminants. Using appropriate products will enhance the longevity and appearance of the finished piece.

How to Add Finishing Touches After Cleaning Engraved Wood

After thoroughly cleaning laser-engraved wood, applying finishing touches enhances the project’s overall appearance. Proper techniques can elevate the surface quality and prolong the wood’s life while highlighting intricate designs.

1. Sanding for Smoothness

Light sanding is an essential step in achieving a refined surface. After cleaning, using fine-grit sandpaper helps eliminate any remaining residue or imperfections. It is crucial to sand gently to avoid damaging the engraved areas.

A recommended approach is to use a sanding block to ensure even pressure. Focus on the edges and corners where raised fibers may remain after cleaning. It might be beneficial to use a microfiber cloth to remove dust generated from sanding, ensuring a clean working environment.

2. Achieving a Professional Finish

To achieve a professional finish, selecting the right products is vital. Specialized wood cleaners can further enhance the wood’s appearance. When using these cleaners, follow the manufacturer’s instructions for the best results.

Additionally, applying a mild detergent mixed with water can help restore the wood’s luster. After cleaning, wiping the surface with a microfiber cloth will remove any streaks. For added protection and shine, consider applying a wood finish or sealant appropriate for the specific type of wood used.

Looking for a Better Laser Engraving Machine for Wood?

Thunder Laser USA makes high-quality machines that are easy to use and give great results. Whether you’re just starting or already have experience, our machines help you make clean, detailed engravings with less mess.

Check out Thunder Laser USA Machines and see how they can improve your wood engraving projects!

Frequently Asked Questions

Cleaning wood after laser engraving requires specific methods to ensure the integrity of the material. Common concerns include the removal of smoke residue, prevention of burn marks, and proper sealing techniques. Below are some key questions and answers related to these topics.

What should you apply to wood after laser engraving?

Apply a clear finish like wood oil, wax, or sealant to protect the engraving and enhance the wood’s appearance.

Do you apply oil to wood before or after laser engraving?

Apply oil after laser engraving to protect the design and bring out the wood’s natural color.

What are the ideal settings for laser engraving wood?

Use low speed and high power for deeper engravings, and high speed with lower power for lighter marks. Always test settings on scrap wood first.

Which type of wood is best for laser engraving?

Light-colored woods create the best contrast with dark laser marks. Alder is a popular choice and comes in various thicknesses, from 1/16″ to 3/4″. Other good options include Basswood, Aspen, Poplar, Hard Maple, Cherry, and Walnut.

How can you remove smoke residue from engraved wood?

Smoke residue can typically be removed with a combination of a dry microfiber cloth and a damp cloth with mild soap. Lightly rubbing the area should clear away the residue without harming the engraving.