Running a CO2 laser engraver the right way helps you get clean and accurate results. Skipping important steps can lead to poor performance or damage.

This checklist guides you through the key actions to keep your machine working at its best. It includes setup, maintenance, and safety checks.

Whether you are just starting or already experienced, following this routine will make your engraving process smoother and more reliable.

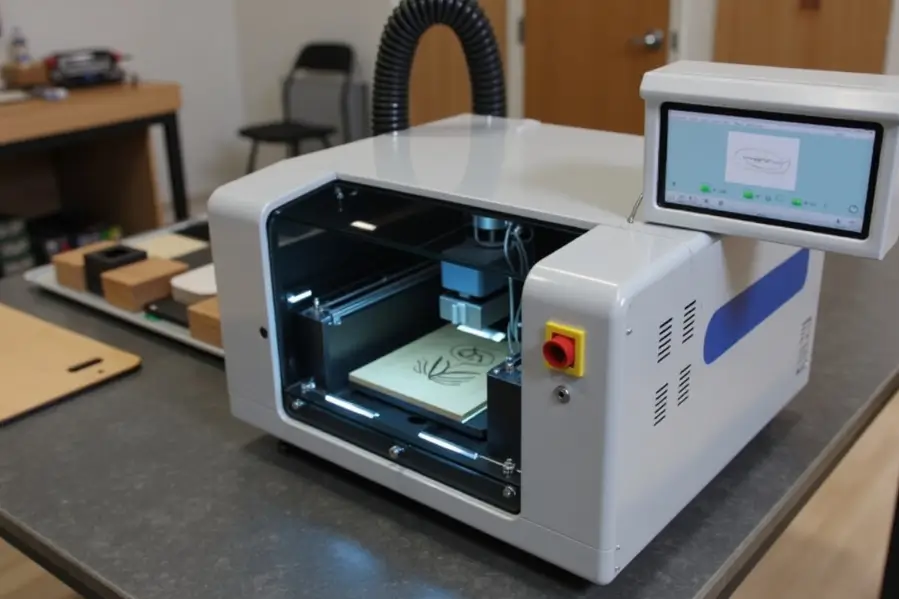

How to Set Up Your CO2 Laser Engraver

Becoming familiar with a CO2 laser engraver involves understanding its operation and prioritizing safety. Proper knowledge and precautions set the foundation for effective and secure usage, enhancing both outcomes and experience.

1. Getting to Know Your CO2 Laser Engraver

A CO2 laser engraver operates using a gas mixture primarily composed of carbon dioxide. This gas generates a powerful beam that can engrave or cut various materials.

Key features to know include:

- Laser Tube: The core component that produces the laser beam. Different wattages affect cutting speed and depth.

- Work Area: The size of the engraving bed determines the maximum size of items that can be processed.

- Software: Familiarity with compatible design and engraving software ensures effective operation.

- Accessories: Items such as rotary axes and chillers may enhance versatility and machine performance.

Understanding these elements helps in maximizing the engraver’s capabilities during creative projects.

2. Essential Safety Guidelines

Safety is paramount when operating a CO2 laser engraver. Following these guidelines will help prevent accidents.

- Wear Protective Gear: Ensure the use of safety glasses specifically designed for laser work. This protects against harmful reflections.

- Establish Safety Zones: Keep work areas clear of flammable materials and ensure proper ventilation to avoid fume accumulation.

- Understand Safety Interlocks: Most CO2 laser machines have safety interlocks to prevent operation when doors are open, ensuring safe use.

- Regular Maintenance: Routine checks of the laser tube and lenses will ensure efficient operation and prevent hazards.

By adhering to these safety measures, users can operate their CO2 laser engravers confidently and effectively.

Best Practices for Operating a CO2 Laser Engraver

Implementing effective operational practices is crucial for successful results with CO2 laser engravers. Focused attention on design preparation, cutting parameters, and system optimization enhances performance and quality.

1. Preparing Your Design Files

Before starting a project, ensure the design files are properly prepared. Common formats like SVG are ideal for laser engraving. Software such as Adobe Illustrator can be used to create or modify designs and export them in the necessary format.

Check that the elements in the design are set correctly, particularly with regard to fill and stroke settings. A filled design will be engraved, while outlines can be set to cut. Review the resolution to ensure optimal quality.

Finally, confirm the focal height is accurate, as this impacts the precision of cuts and engravings. The correct focal height allows the laser to concentrate its energy effectively on the material.

2. Laser Cutting and Engraving Parameters

Choosing the right settings is key to getting clean and accurate results. Focus on adjusting power, speed, and frequency based on your material and project type. For engraving, lower speed and higher power often give better detail. Cutting thicker materials may need higher power and slower speed.

Always check the manufacturer’s recommendations for specific materials like plywood or acrylic. Adjust frequency settings as needed since different materials respond differently. Running test samples helps you fine-tune these settings and achieve consistent results.

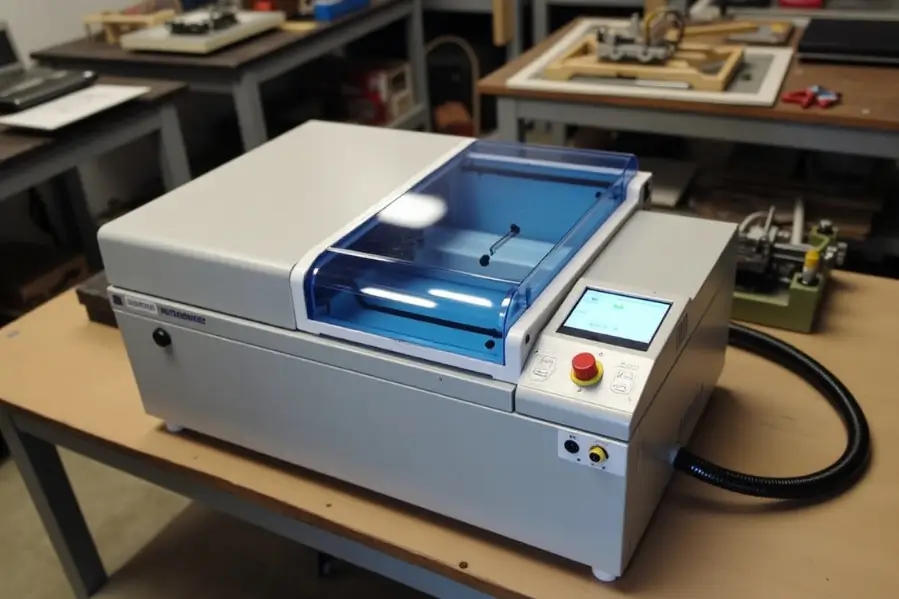

3. Improving Laser Engraving with Air Assist and Cooling

Using air assist helps keep the engraving area clean by blowing away smoke and debris. This results in sharper lines and better detail.

Cooling is just as important. A water cooling system prevents the CO2 laser from overheating and helps maintain consistent power. This protects the laser tube and improves performance.

Check both systems regularly. Clean filters and make sure airflow and cooling are working properly. Together, air assist and cooling ensure smoother operation and higher-quality results.

Regular Maintenance and Troubleshooting

Maintaining a CO2 laser engraver involves specific tasks that ensure its efficiency and longevity. Regular attention to maintenance and troubleshooting can prevent significant issues and extend the machine’s lifespan.

1. Daily and Weekly Maintenance Tasks

Regular maintenance keeps your CO2 laser engraver running safely and smoothly. Daily and weekly checks help prevent damage and extend the life of your machine.

Daily tasks:

- Clean the lens and mirrors using proper cleaning solutions

- Check the fume extractor and make sure the exhaust vent is clear

- Remove any dust or debris from the work area

Weekly tasks:

- Check coolant levels and refill if needed

- Lubricate moving parts to reduce friction and wear

- Inspect belts, rails, and wiring for signs of damage or wear

Keep a maintenance checklist to stay organized and follow the specific guidelines for your machine. Consistent care improves both performance and safety.

2. Alignment and Calibration Procedures

Proper alignment ensures the laser beam hits the right spot every time. Over time, mirror positions can shift, so it’s important to check and adjust them regularly.

Calibration helps verify that power, speed, and other settings are working correctly. If these are off, your cuts or engravings may look uneven or weak.

Make alignment and calibration part of your regular maintenance routine. Using a checklist can help you stay on track and get consistent, high-quality results.

3. Extending the Life of Your CO2 Laser Engraver

Regular maintenance helps prevent problems and extends the life of your CO2 laser engraver. Catching small issues early can save you from costly repairs later.

A clean workspace is just as important. Dust and debris can get inside the machine and cause damage over time. Keep the area around your engraver clear.

Combine daily cleaning, routine alignment, and calibration into one maintenance plan. This keeps your machine running smoothly and improves the quality of your work.

Tips for Automating Your Laser Engraving Process

Utilizing the right software tools effectively can significantly enhance the laser engraving process. Proper management of laser settings, conducting test runs, and following best practices are key factors in achieving optimal results.

1. Efficient Use of Software Tools

LightBurn is one of the leading software choices for CO2 laser engravers. It allows users to control their machines with precision. Familiarity with its features can lead to better performance.

Users should always configure laser settings based on material type. This includes adjusting power and speed settings to avoid burning or incomplete engraving.

Conducting test runs on scrap material is a best practice. It helps identify optimal parameters before final projects.

Additionally, keeping a log of successful settings can save time on future projects. Regularly updating software ensures users benefit from the latest features and improvements.

Final Thoughts

Getting the best results from a CO2 laser engraver comes down to proper setup, regular maintenance, and safe operation. A simple routine can improve quality and extend the life of your machine.

Ready to get started or upgrade?

Explore our top CO2 laser engravers and find the right tools for your next project.

Frequently Asked Questions

1. What do you need to run a CO2 laser?

To run a CO2 laser engraver, you need a few key components. These include the laser machine itself, a water cooling system to prevent overheating, and proper ventilation to remove fumes. You’ll also need compatible laser software and safe materials for engraving. Having all these in place ensures safe, smooth, and efficient operation.

2. What to look for when buying a CO2 laser?

When buying a CO2 laser machine, focus on key factors like cutting accuracy, speed, and overall efficiency. Make sure the machine matches your application needs, whether for engraving or cutting. Check the expected maintenance costs, service life, and the support offered by the manufacturer. Research the market in advance to compare models and choose the one that fits your budget and project goals.

3. Do CO2 lasers need gas?

Yes, CO2 lasers use a mix of gases to generate the laser beam. Carbon dioxide is the main gas, while others like nitrogen and oxygen may be used to improve cutting quality depending on the material and application.

4. What do I need to start laser engraving?

To start laser engraving, you need a laser engraving machine, design software like LightBurn or Inkscape, and materials that are safe and compatible with your laser. Good ventilation and basic safety gear are also important for safe operation.

5. What is the disadvantage of CO2 laser?

CO2 lasers can cause side effects like redness, peeling, or skin sensitivity when used for medical treatments. In industrial use, disadvantages include high initial cost, regular maintenance, and the need for proper ventilation. Careful handling and setup are important to avoid issues.