Laser Cutting in the Packaging Industry

Laser-cut packaging is undergoing a revolution, and there’s still time to tap into this market while it’s on the brink of a boom. With consumers demanding more than ever when it comes to packaging design and sustainability and manufacturers finding new, smart ways of keeping products fresher for longer, the packaging industry is crying out for innovators.

With an affordable laser system from Thunder Laser USA, you can become your own boss, quickly recoup your initial investment and start making a ton of cash in no time.

Packaging Design and Function

Laser machines have changed the face of the manufacturing industry, with industrial businesses around the world using laser cutters to improve the quality and customization of packaging and increase production speed. The packaging sector was one of the first to realize the potential lasers have for innovation in an industry with growing demands.

As the population increases and demand for products continues to grow — and with more people setting up small businesses and creating consumer goods than ever — the demand for packaging continues to steadily increase. Where it was once seen as something mainly functional with some marketing and informative benefits, the true impact of packaging is now better understood.

Consumer Trends

Unboxing has become something of a phenomenon on social media, where companies can showcase products as influencers open their products in front of millions of viewers. This is great marketing not only for the company selling the product but also for the packaging manufacturer.

What’s more, with a big push for consumers to understand the impact of potential dangers to the environment such as single-use plastic and careless waste, the packaging industry is stepping up. If you can make laser-cut packaging that’s creative, sustainable and functional, you’ve got a winner.

What Do Packages Do?

The majority of sectors rely on packaging to some extent, so there’s an enormous market to tap into. Let’s take a look at some of the primary functions of packaging:

- Protect the product inside the package from external contamination

- As a form of advertising to inspire the consumer to choose the product when they see it on a shelf or delight the customer as they receive the package in the mail and unbox it

- Inform the customer about key information such as ingredients, macros, expiry dates, batch codes and barcodes

- Practicality is another major consideration when it comes to packaging design; containers must be easy to open, handle and transport safely

Laser Cutting Cardboard

Cardboard is the most popular material for a package, and it’s one of the materials CO2 lasers are most effective at laser engraving, laser cutting and laser marking. Practically every business in the world needs cardboard boxes, and they often need more than one type. Below are the most popular uses for cardboard boxes in the packaging industry.

Transportation

Inner packaging usually needs to be pretty and intricate, with a mixture of useful information and marketing content. However, outer packaging for transportation is all about practicality and sustainability.

Consumers don’t want to see plastic tape anymore, with paper versions taking over. They don’t want unnecessary waste, but of course, the package must be sturdy enough to protect the goods inside.

Boxes for Consumers

If you’re the creative type, packaging for consumers is where you can express your inner artist and help manufacturers advertise their products and keep customers happy.

From cute drawings to quotes, logos and QR codes, you can make packages that are highly functional from a business perspective. They’ll also look stunning enough to inspire anyone who sees a person open an item contained in your packaging to want to purchase that item themselves.

Laser Engraver

Now that you understand how important a role packaging plays in the consumer goods industry, we’ll explain how clever entrepreneurs use laser cutting and engraving to design and build packages.

Laser engraving and laser marking are similar processes, with the former leaving a deeper imprint on the material than marking, which only occurs superficially. You can imprint expiration dates, information, barcodes, text and logos using these laser cutting processes.

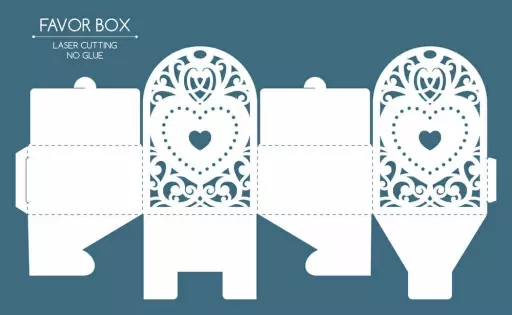

Laser-Cut Packaging

With laser cutting, the laser beam dissolves the material according to a path you program into a computer. CO2 lasers generally leave perfectly clean edges on most materials, so the final piece won’t require any additional finishing once the laser cutter has finished processing it.

You can laser-cut openings and windows to make viewing the contents of a package easier, cut folding cartons for assembly and create details like easy-open tabs and tear openings.

Laser Cutting: Perforation

It’s possible to use a CO2 laser on pulse mode to create perforations in packages that are required for a range of purposes, from easy-tear openings to ensuring produce has just the right amount of air to stay fresh.

Why Use a CO2 Laser?

While laser engraving and cutting might be more strongly associated with materials such as acrylic and wood, it’s highly effective with paper, paperboard and cardboard. Laser manufacturing is high-speed, high-quality and efficient due to the potential for automation, and it offers the opportunity to experiment with a range of applications.

Below are the most frequently used applications of laser technology in the production of packages:

- Making boxes using paper or cardboard, which can be perforated, cut and marked — you can design boxes as traditionally or on-brand as you choose

- Food crates and similar using MDF and other thin wood derivatives

- Food-safe plastics and thermoplastic film polymers

- Aluminized plastic films

Creative Packaging Is a Growing Industry

Laser cutting is a big deal in the world of packages, and it’s about to get even bigger. You can buy an affordable laser system from Thunder Laser USA and quickly make back your investment by becoming an entrepreneur in the packaging sector.